— Your Prime Source for Advanced Relays And Water Valves —

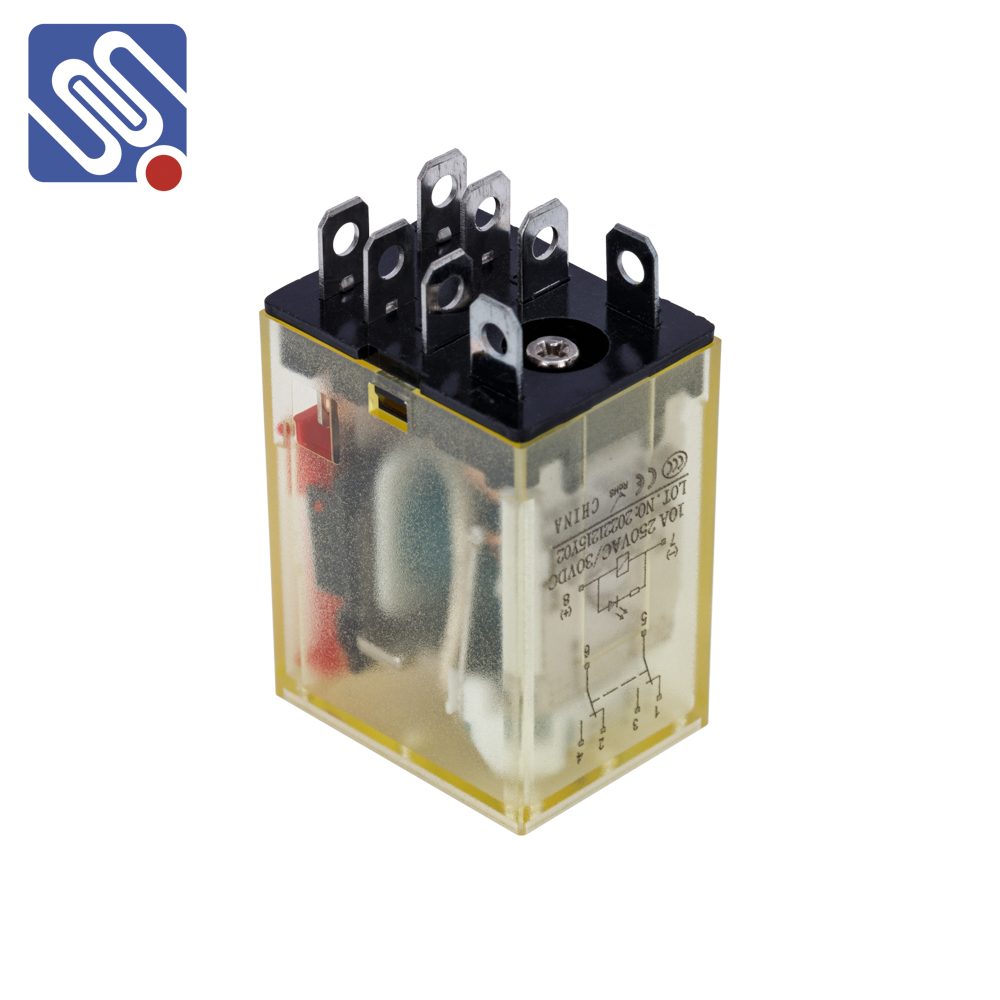

Technical Specifications

Contact Configuration: DPDT (Double Pole Double Throw)

Rated Voltage: DC:5,6,12,24,48,110V AC:6,12,24,48,120,220/240V

Rated Current: 10A 250VAC/15A/250VAC

Operating Temperature Range: -40°C to 85°C

Coil Power:DC:0.9-1.1W AC:1.2-1.8W

Mechanical Life: ≥1,000,000 cycles

Electrical Life: ≥100,000 cycles

Technical Specifications

Contact Configuration: DPDT (Double Pole Double Throw)

Rated Voltage: DC:5,6,12,24,48,110V AC:6,12,24,48,120,220/240V

Rated Current: 10A 250VAC/15A/250VAC

Operating Temperature Range: -40°C to 85°C

Coil Power:DC:0.9-1.1W AC:1.2-1.8W

Mechanical Life: ≥1,000,000 cycles

Electrical Life: ≥100,000 cycles

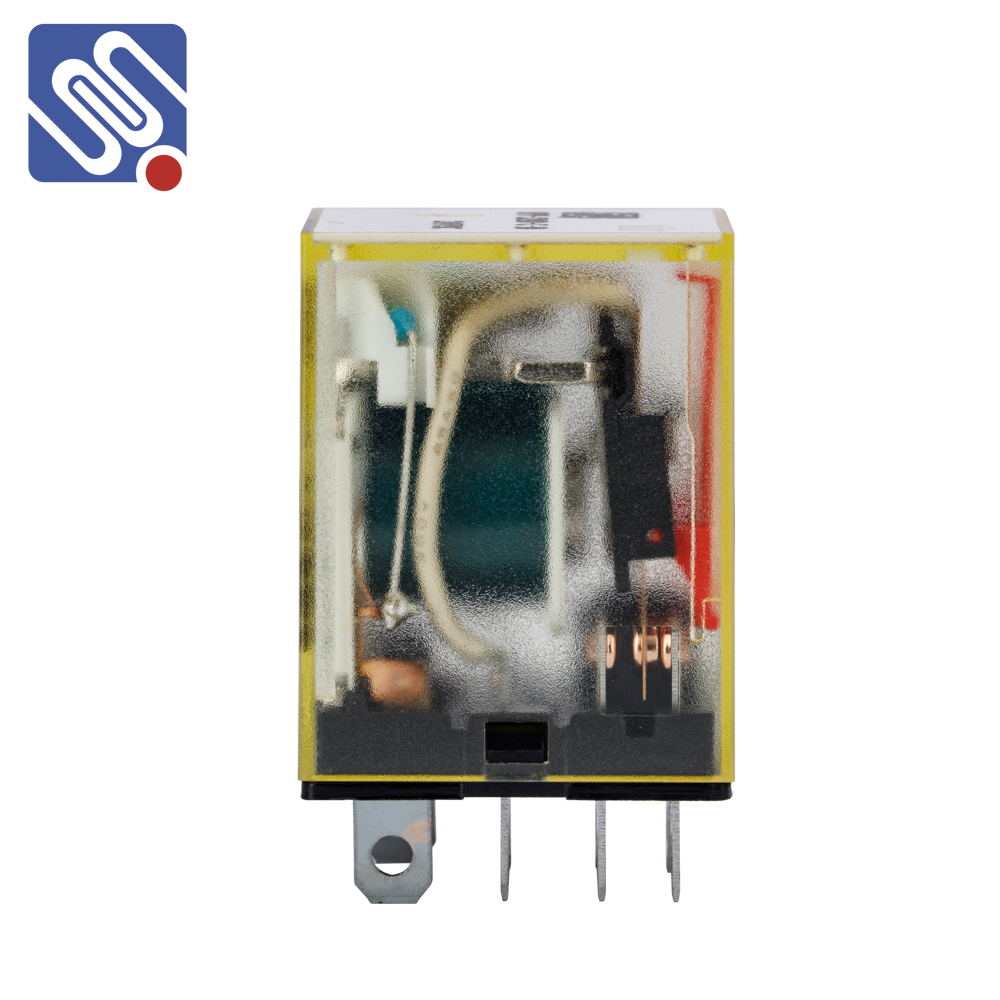

Product Principle

The Industrial Control Relay works by using an electromagnetic coil. When the coil is energized, it generates a magnetic field that pulls the relay’s movable contacts into position, completing the circuit and allowing current to flow. When the coil is de-energized, the contacts return to their default position, breaking the circuit.

Difference:

1.The LED indicator shows coil energization status, with green for DC and red for AC

2.The Mechanical Indicator shows when the relay’s contacts are engaged, confirming that the relay has switched its contacts.

Product Principle

The Industrial Control Relay works by using an electromagnetic coil. When the coil is energized, it generates a magnetic field that pulls the relay’s movable contacts into position, completing the circuit and allowing current to flow. When the coil is de-energized, the contacts return to their default position, breaking the circuit.

Difference:

1.The LED indicator shows coil energization status, with green for DC and red for AC

2.The Mechanical Indicator shows when the relay’s contacts are engaged, confirming that the relay has switched its contacts.

Support your OEM/ODM needs and provide one-stop customized solutions